- Products Description

- Main Function

- Parameters

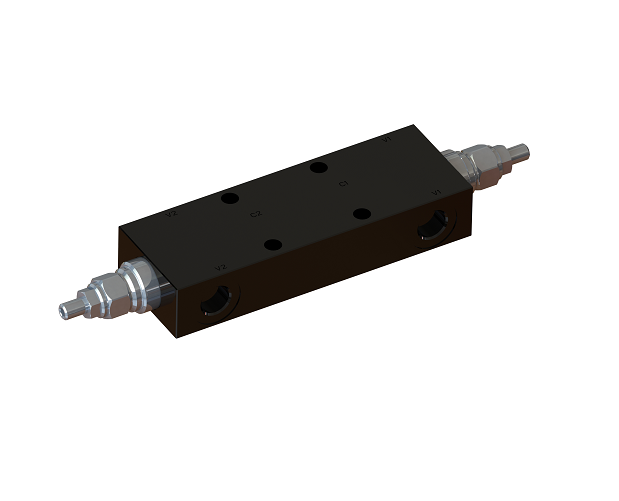

Screw-in Load holding valves is a high-performance control component designed specifically for hydraulic systems, used to maintain system balance and stability under different load conditions.

Principle of Work

Screw-in Load holding valves adjust the pressure and flow in the system through the spring and valve core inside the valve.

During normal operation: Keep the system load running smoothly within the set pressure range.

When the load changes: When the system load changes or a reverse force is generated, the valve core automatically adjusts according to the actual pressure to prevent the actuator from losing control of speed or hydraulic shock.

Characteristics

Compact structure:

Adopting a threaded insertion design reduces external piping and is suitable for integrated installation, saving space.

Efficient balance control:

When the load changes or reverse impact occurs, it can maintain the smooth operation of the actuator and prevent slipping or overspeeding.

Security protection:

Provide overpressure protection to prevent damage to actuator components caused by excessive system pressure.

Easy to maintain:

Easy to replace or repair, without the need to disassemble the entire hydraulic system.

Applications

Screw-in Load holding valves widely used in hydraulic systems that require load maintenance and stall prevention, including:

Construction machinery: arm frames or suspension systems for excavators, cranes, loaders, etc.

Industrial equipment: such as hydraulic lifting platforms, mold clamping systems, etc.

Ships and marine equipment: load control for stable lifting equipment.

Material handling equipment: such as balance control in forklifts and elevators.

Summary

Screw-in Load holding valves With its compact design, flexible installation method, and efficient balance control capability, it has become an indispensable and important component in modern hydraulic systems. It not only improves the stability and safety of the system operation, but also simplifies the overall layout and maintenance of the hydraulic system.

Screw-in Load holding valves is a high-performance control component designed specifically for hydraulic systems, used to maintain system balance and stability under different load conditions.

Principle of Work

· Screw-in Load holding valves adjust the pressure and flow in the system through the spring and valve core inside the valve.

· During normal operation: Keep the system load running smoothly within the set pressure range.

· When the load changes: When the system load changes or a reverse force is generated, the valve core automatically adjusts according to the actual pressure to prevent the actuator from losing control of speed or hydraulic shock.

Characteristics

Compact structure:

· Adopting a threaded insertion design reduces external piping and is suitable for integrated installation, saving space.

Efficient balance control:

· When the load changes or reverse impact occurs, it can maintain the smooth operation of the actuator and prevent "rolling" or overspeed phenomenon.

Security protection:

· Provide overpressure protection to prevent damage to actuator components caused by excessive system pressure.

Easy to maintain:

· Easy to replace or repair, without the need to disassemble the entire hydraulic system.

Applications

· Screw-in Load holding valves widely used in hydraulic systems that require load maintenance and stall prevention, including:

· Construction machinery: arm frames or suspension systems for excavators, cranes, loaders, etc.

· Industrial equipment: such as hydraulic lifting platforms, mold clamping systems, etc.

· Ships and marine equipment: load control for stable lifting equipment.

· Material handling equipment: such as balance control in forklifts and elevators.

Summary

· Screw-in Load holding valves With its compact design, flexible installation method, and efficient balance control capability, it has become an indispensable and important component in modern hydraulic systems. It not only improves the stability and safety of the system operation, but also simplifies the overall layout and maintenance of the hydraulic system.

· Screw-in Load holding valves adjust the pressure and flow in the system through the spring and valve core inside the valve.

· During normal operation: Keep the system load running smoothly within the set pressure range.

· When the load changes: When the system load changes or a reverse force is generated, the valve core automatically adjusts according to the actual pressure to prevent the actuator from losing control of speed or hydraulic shock.

Characteristics

Compact structure:

· Adopting a threaded insertion design reduces external piping and is suitable for integrated installation, saving space.

Efficient balance control:

· When the load changes or reverse impact occurs, it can maintain the smooth operation of the actuator and prevent "rolling" or overspeed phenomenon.

Security protection:

· Provide overpressure protection to prevent damage to actuator components caused by excessive system pressure.

Easy to maintain:

· Easy to replace or repair, without the need to disassemble the entire hydraulic system.

Applications

· Screw-in Load holding valves widely used in hydraulic systems that require load maintenance and stall prevention, including:

· Construction machinery: arm frames or suspension systems for excavators, cranes, loaders, etc.

· Industrial equipment: such as hydraulic lifting platforms, mold clamping systems, etc.

· Ships and marine equipment: load control for stable lifting equipment.

· Material handling equipment: such as balance control in forklifts and elevators.

Summary

· Screw-in Load holding valves With its compact design, flexible installation method, and efficient balance control capability, it has become an indispensable and important component in modern hydraulic systems. It not only improves the stability and safety of the system operation, but also simplifies the overall layout and maintenance of the hydraulic system.