- Products Description

- Main Function

- Parameters

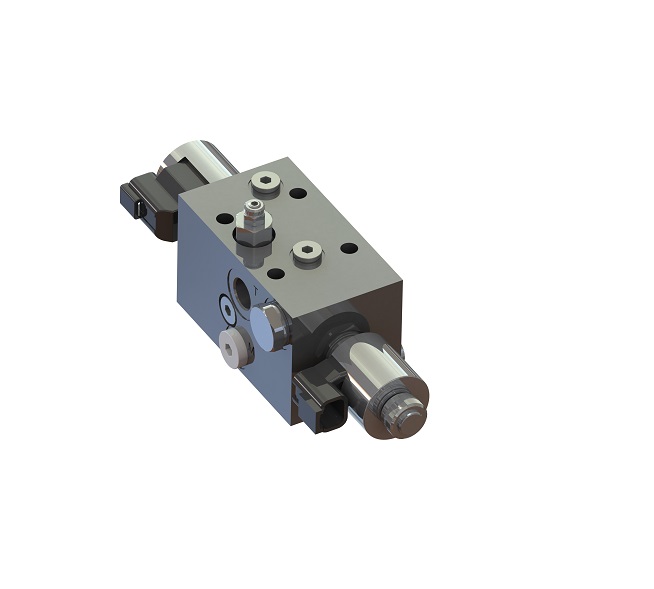

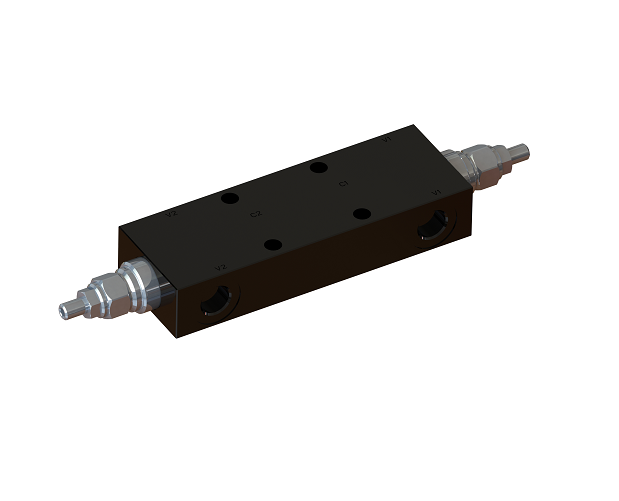

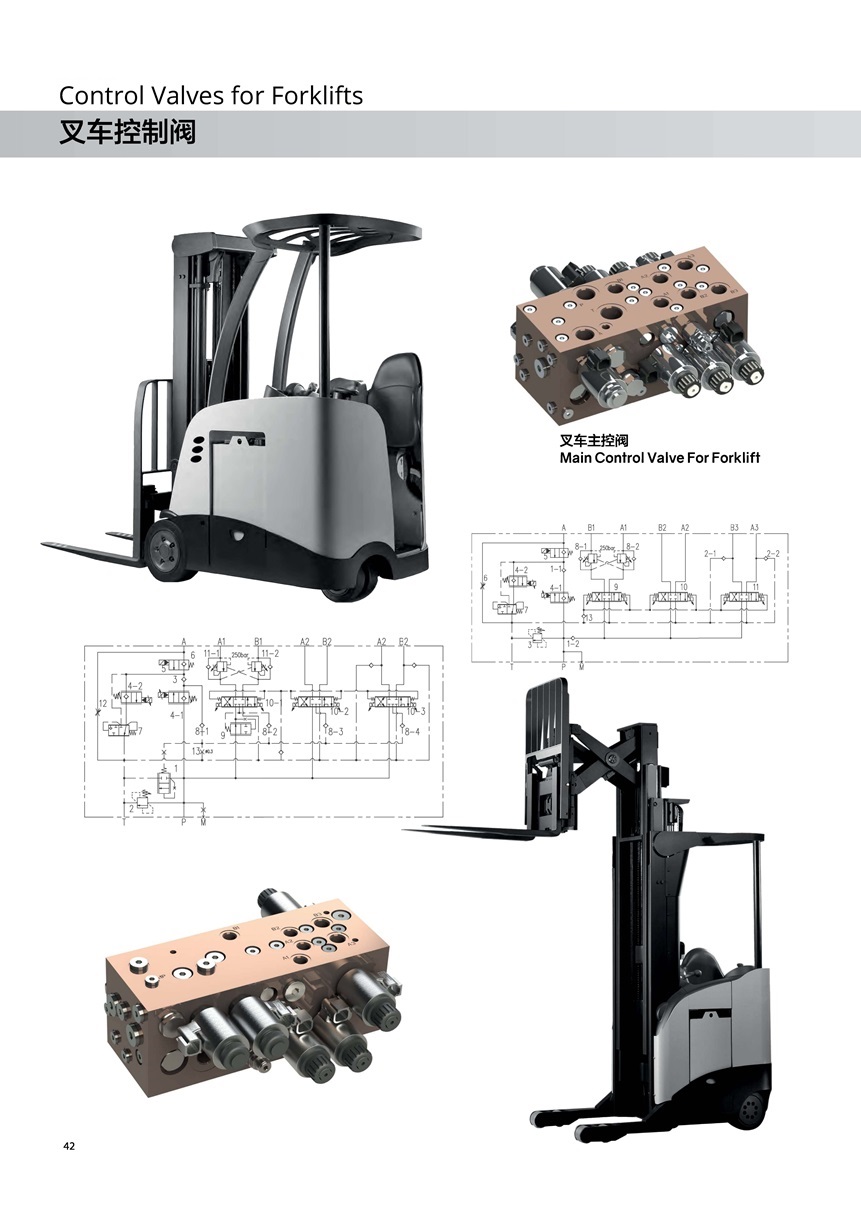

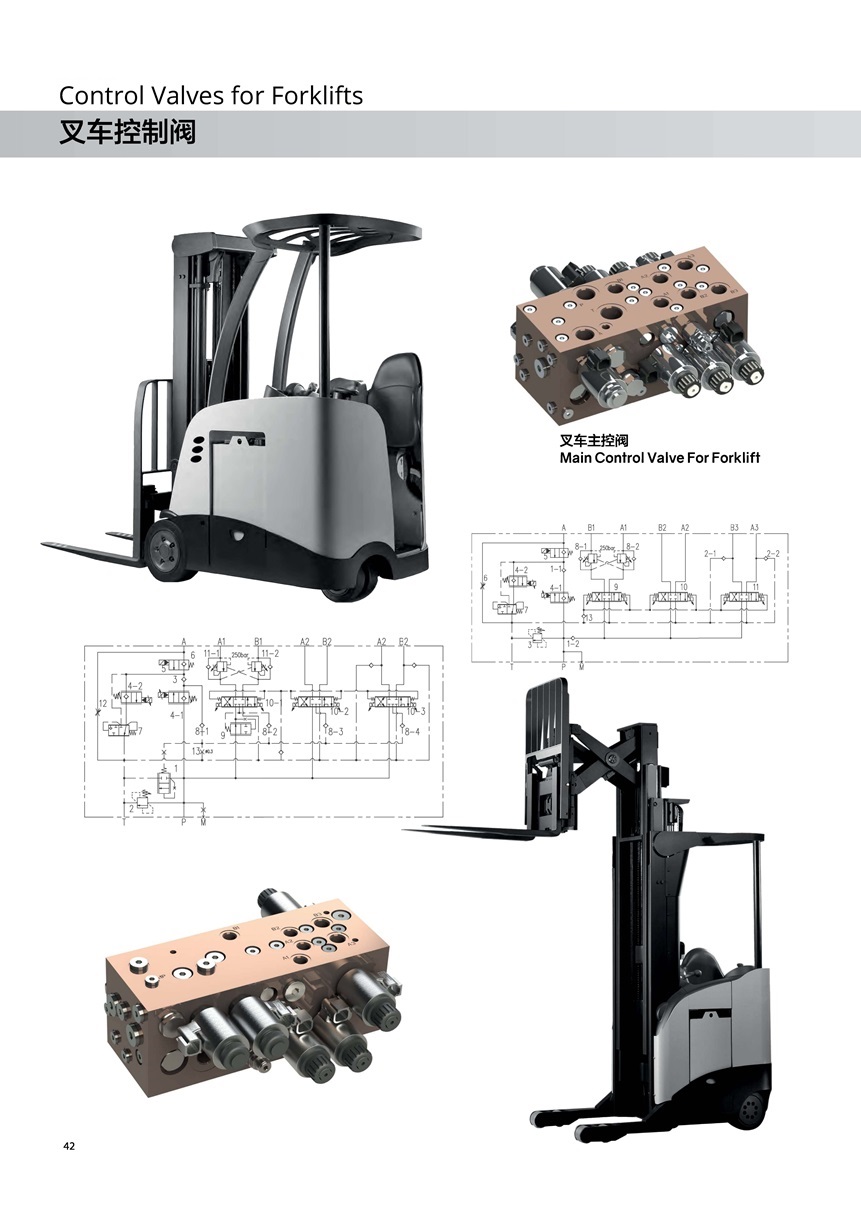

Cartridge Integrated valve group is a hydraulic control system module that integrates multiple Cartridge valves into one valve block. It integrates functions such as pressure control, flow control, and direction control into a compact integrated block, achieving precise control of the hydraulic system. Through Modular Design, the valve group simplifies the installation, pipeline connection, and maintenance of the hydraulic system, greatly improving the reliability and efficiency of the system.

Principle of Work

Cartridge valves,The integrated valve group adopts various types of Cartridge valves, such as relief valves, load holding valves, pressure reducing valves, one-way valves, and electromagnetic directional valves, which are connected through internal channels within the integrated block to form a complex hydraulic circuit. Each plug-in valve works independently and achieves comprehensive control of hydraulic system pressure, flow rate, and direction through precise coordination.

Characteristics

Modular Design:

Integrating multiple functional valves into one valve block reduces pipeline connection points, lowers leakage risks, and improves overall system stability.

Compact structure:

The integrated structure greatly saves space and is suitable for installation in narrow equipment spaces.

Diversified functions:

Different types of plug-in valves can be flexibly configured according to system requirements to achieve various control functions, such as pressure regulation, flow distribution, and directional control.

Easy maintenance:

Plug in valves are easy to disassemble and replace, without the need to disassemble the entire hydraulic system, resulting in low maintenance costs.

Efficient performance:

Internal channel optimization design reduces energy loss and improves system efficiency.

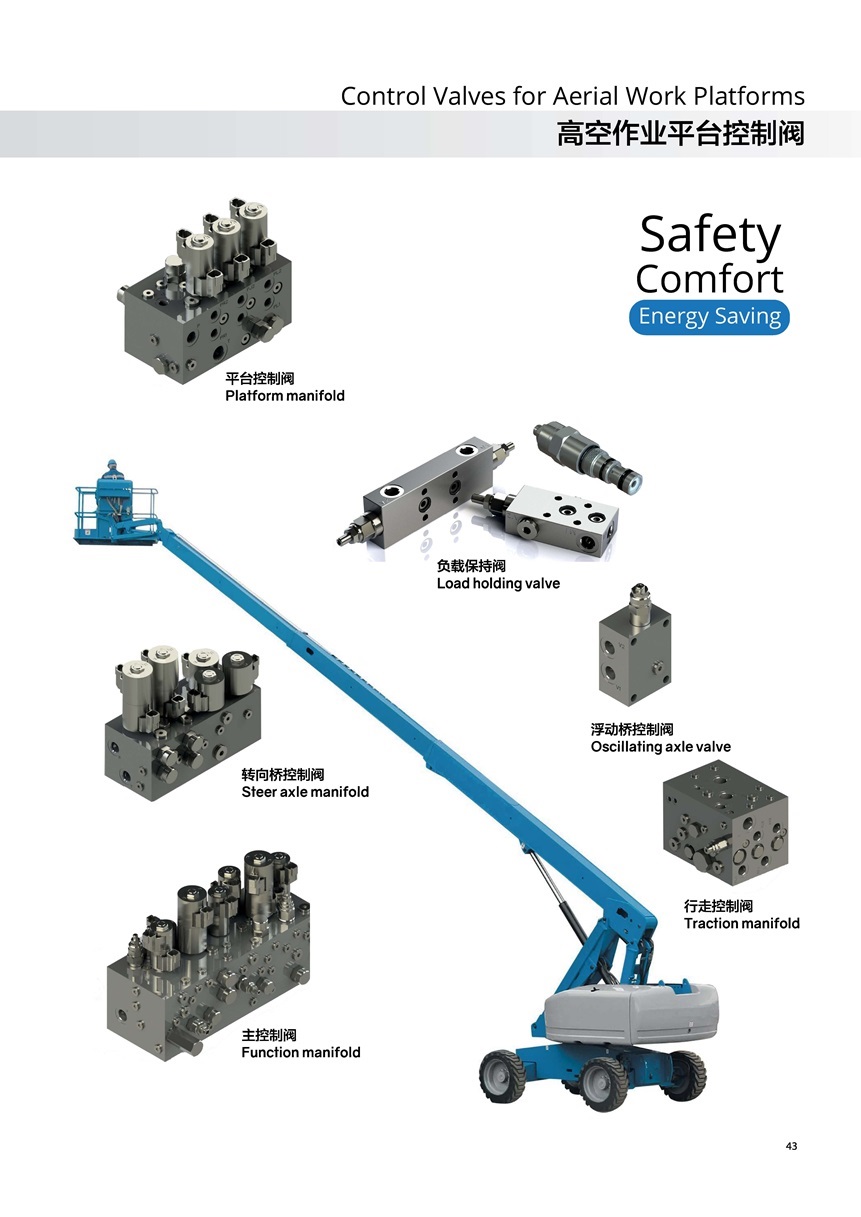

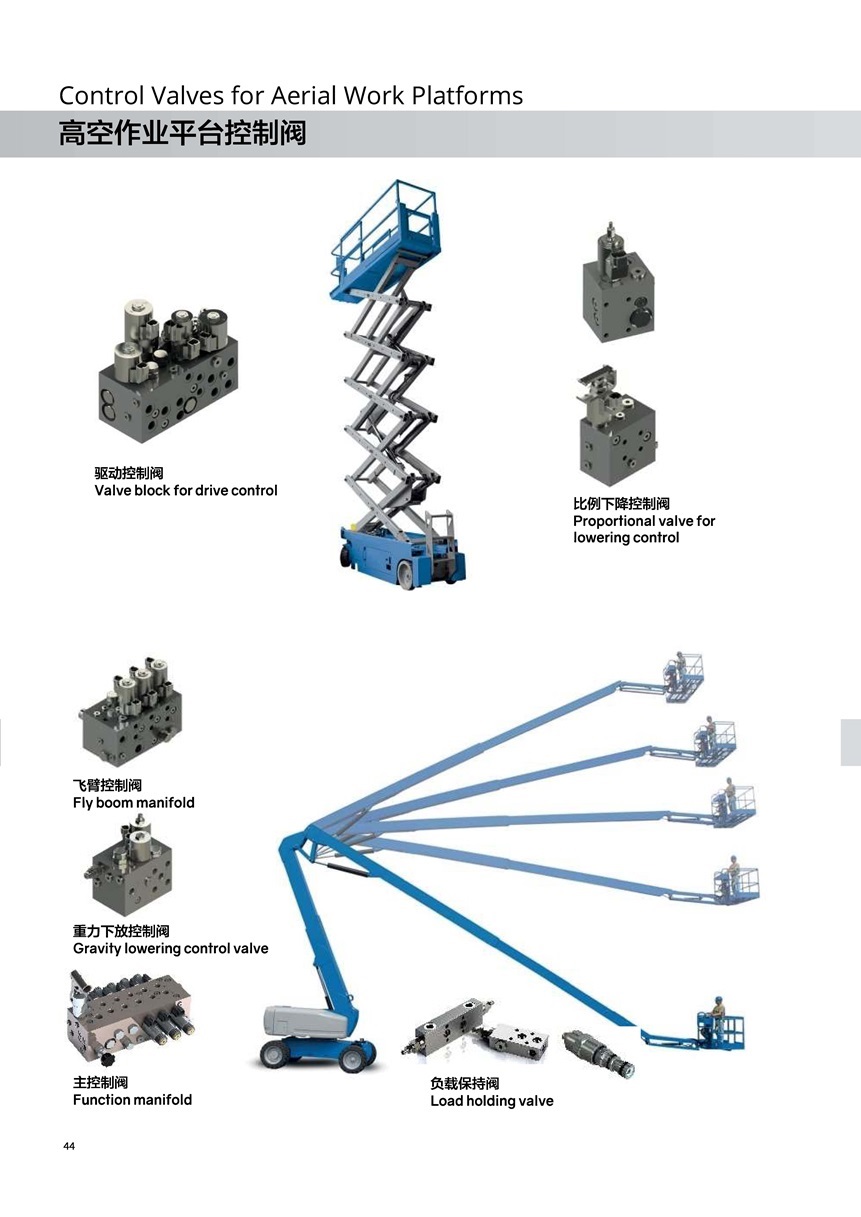

Applications

Cartridge valves,Integrated valve groups are widely used in hydraulic systems that require highly integrated and complex control functions, such as:

Construction machinery: hydraulic control units for excavators, cranes, and other equipment.

Industrial automation equipment: integrated hydraulic control systems for CNC machine tools and hydraulic stamping machines.

Agricultural machinery: such as multifunctional hydraulic control systems for combine harvesters.

Ship equipment: ship lifting, servo control system.

New energy equipment: hydraulic control system for wind power generation, etc.

Cartridge valves,Integrated valve group is a hydraulic control system module that integrates multiple Cartridge valves into one valve block. It integrates functions such as pressure control, flow control, and direction control into a compact integrated block, achieving precise control of the hydraulic system. Through Modular Design, the valve group simplifies the installation, pipeline connection, and maintenance of the hydraulic system, greatly improving the reliability and efficiency of the system.

Principle of Work

· Cartridge valves,The integrated valve group adopts various types of Cartridge valves, such as relief valves, load holding valves, pressure reducing valves, one-way valves, and electromagnetic directional valves, which are connected through internal channels within the integrated block to form a complex hydraulic circuit. Each plug-in valve works independently and achieves comprehensive control of hydraulic system pressure, flow rate, and direction through precise coordination.

Characteristics

Modular Design:

· Integrating multiple functional valves into one valve block reduces pipeline connection points, lowers leakage risks, and improves overall system stability.

Compact structure:

· The integrated structure greatly saves space and is suitable for installation in narrow equipment spaces.

Diversified functions:

· Different types of plug-in valves can be flexibly configured according to system requirements to achieve various control functions, such as pressure regulation, flow distribution, and directional control.

Easy maintenance:

· Plug in valves are easy to disassemble and replace, without the need to disassemble the entire hydraulic system, resulting in low maintenance costs.

Efficient performance:

· Internal channel optimization design reduces energy loss and improves system efficiency.

Applications

· Cartridge valves,Integrated valve groups are widely used in hydraulic systems that require highly integrated and complex control functions, such as:

· Construction machinery: hydraulic control units for excavators, cranes, and other equipment.

· Industrial automation equipment: integrated hydraulic control systems for CNC machine tools and hydraulic stamping machines.

· Agricultural machinery: such as multifunctional hydraulic control systems for combine harvesters.

· Ship equipment: ship lifting, servo control system.

· New energy equipment: hydraulic control system for wind power generation, etc.

· Cartridge valves,The integrated valve group adopts various types of Cartridge valves, such as relief valves, load holding valves, pressure reducing valves, one-way valves, and electromagnetic directional valves, which are connected through internal channels within the integrated block to form a complex hydraulic circuit. Each plug-in valve works independently and achieves comprehensive control of hydraulic system pressure, flow rate, and direction through precise coordination.

Characteristics

Modular Design:

· Integrating multiple functional valves into one valve block reduces pipeline connection points, lowers leakage risks, and improves overall system stability.

Compact structure:

· The integrated structure greatly saves space and is suitable for installation in narrow equipment spaces.

Diversified functions:

· Different types of plug-in valves can be flexibly configured according to system requirements to achieve various control functions, such as pressure regulation, flow distribution, and directional control.

Easy maintenance:

· Plug in valves are easy to disassemble and replace, without the need to disassemble the entire hydraulic system, resulting in low maintenance costs.

Efficient performance:

· Internal channel optimization design reduces energy loss and improves system efficiency.

Applications

· Cartridge valves,Integrated valve groups are widely used in hydraulic systems that require highly integrated and complex control functions, such as:

· Construction machinery: hydraulic control units for excavators, cranes, and other equipment.

· Industrial automation equipment: integrated hydraulic control systems for CNC machine tools and hydraulic stamping machines.

· Agricultural machinery: such as multifunctional hydraulic control systems for combine harvesters.

· Ship equipment: ship lifting, servo control system.

· New energy equipment: hydraulic control system for wind power generation, etc.