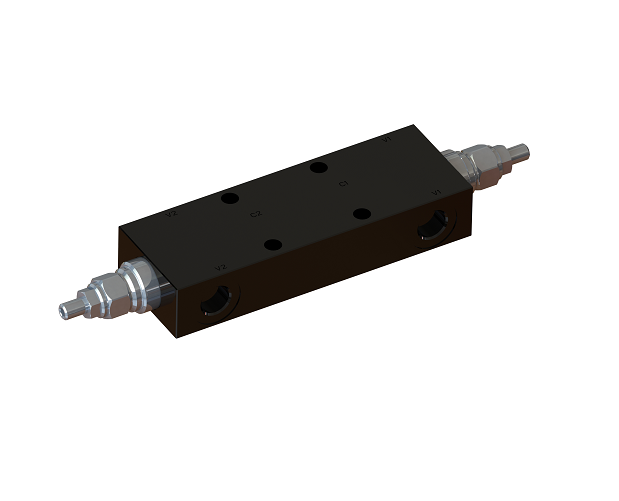

- Products Description

- Main Function

- Parameters

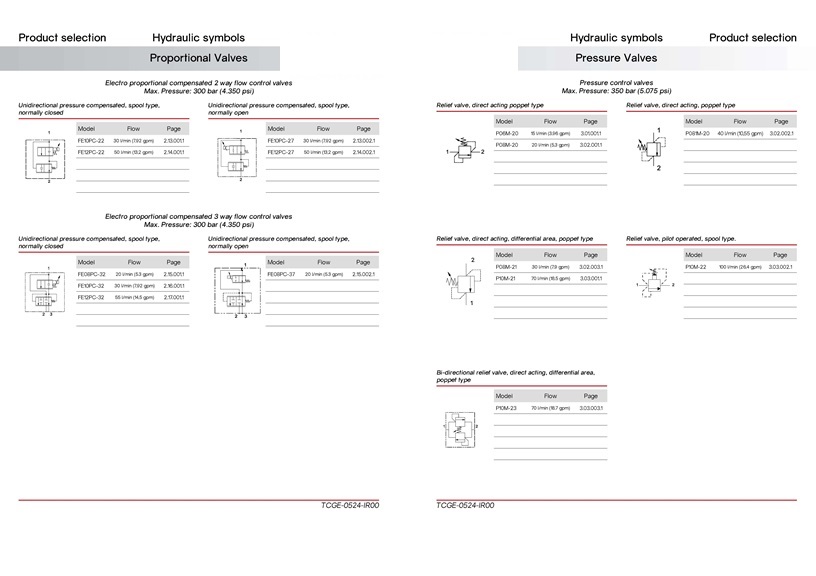

Pressure control valves are key components used to control pressure in hydraulic systems, which can maintain system stability, protect component safety, and optimize work efficiency. According to different functions, pressure control valves mainly include relief valves, pressure reducing valves, and sequence valves, which are widely used in various industrial equipment, construction machinery, and automation systems.

Principle of Work

Pressure control valves control system pressure or maintain pressure balance by sensing the pressure of hydraulic oil and adjusting the position of the valve core. Usually, there are springs and valve cores inside the valve. When the system pressure exceeds the set value, the valve core moves, opens the passage, releases excess pressure or changes the oil flow direction, thereby protecting the system from high pressure damage or maintaining the required pressure level.

Main types

Relief valve

Function:Prevent excessive system pressure and provide safety protection.

Application:When the system pressure exceeds the set value, the excess hydraulic oil is automatically returned to the oil tank.

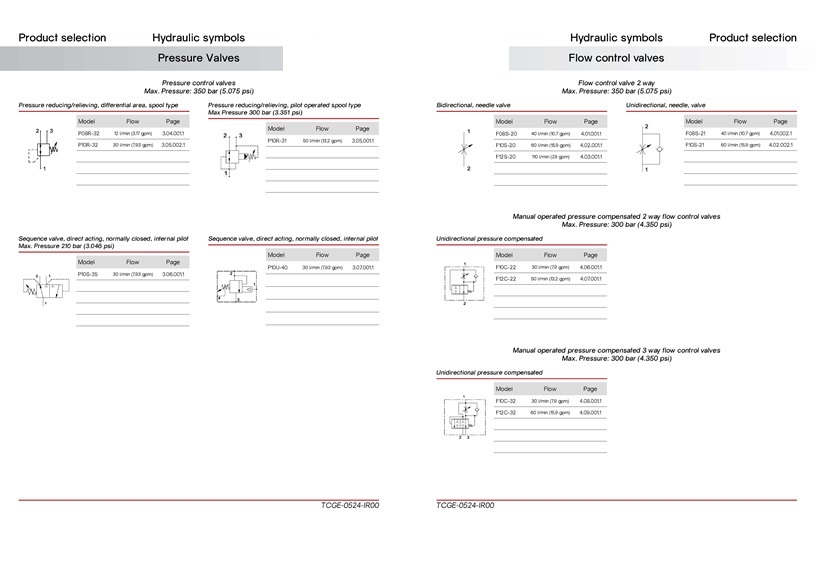

Pressure relief valve

Function:Reduce and stabilize the pressure of specific branch circuits.

Application:Provide different pressure requirements for different components in the same system.

Sequence valve

Function:Start different hydraulic actuators in sequence.

Application:In a multi actuator system, control the working sequence of the executing elements.

Characteristics

High pressure stability: effectively maintaining the required pressure of the system to ensure stable operation of the equipment.

Security protection: prevent overvoltage damage to the system and extend equipment lifespan.

Fast response speed: able to quickly respond to pressure changes and adapt to dynamic working conditions.

Compact structure:Simple design, easy to install and maintain.

Applications

Hydraulic pressure control valves are widely used in various hydraulic systems, such as:

Engineering machinery: Control working pressure in equipment such as excavators and cranes.

Industrial equipment: safety protection and pressure regulation of systems such as hydraulic machine tools and injection molding machines.

Automotive hydraulic system: used for pressure control of braking and suspension systems.

Through precise pressure control, hydraulic pressure control valves ensure efficient and stable operation of the system, and provide guarantees for equipment safety, which is an indispensable and important component of modern hydraulic technology.

Pressure control valves are key components used to control pressure in hydraulic systems, which can maintain system stability, protect component safety, and optimize work efficiency. According to different functions, pressure control valves mainly include relief valves, pressure reducing valves, and sequence valves, which are widely used in various industrial equipment, construction machinery, and automation systems.

Principle of Work

· Pressure control valves control system pressure or maintain pressure balance by sensing the pressure of hydraulic oil and adjusting the position of the valve core. Usually, there are springs and valve cores inside the valve. When the system pressure exceeds the set value, the valve core moves, opens the passage, releases excess pressure or changes the oil flow direction, thereby protecting the system from high pressure damage or maintaining the required pressure level.

Main types

· Relief valve

Function:Prevent excessive system pressure and provide safety protection.

Application:When the system pressure exceeds the set value, the excess hydraulic oil is automatically returned to the oil tank.

· Pressure relief valve

Function:Reduce and stabilize the pressure of specific branch circuits.

Application:Provide different pressure requirements for different components in the same system.

· Sequence valve

Function:Start different hydraulic actuators in sequence.

Application:In a multi actuator system, control the working sequence of the executing elements.

Characteristics

· High pressure stability: effectively maintaining the required pressure of the system to ensure stable operation of the equipment.

· Security protection: prevent overvoltage damage to the system and extend equipment lifespan.

· Fast response speed: able to quickly respond to pressure changes and adapt to dynamic working conditions.

· Compact structure:Simple design, easy to install and maintain.

Applications

· Hydraulic pressure control valves are widely used in various hydraulic systems, such as:

· Engineering machinery: Control working pressure in equipment such as excavators and cranes.

· Industrial equipment: safety protection and pressure regulation of systems such as hydraulic machine tools and injection molding machines.

· Automotive hydraulic system: used for pressure control of braking and suspension systems.

· Through precise pressure control, hydraulic pressure control valves ensure efficient and stable operation of the system, and provide guarantees for equipment safety, which is an indispensable and important component of modern hydraulic technology.

· Pressure control valves control system pressure or maintain pressure balance by sensing the pressure of hydraulic oil and adjusting the position of the valve core. Usually, there are springs and valve cores inside the valve. When the system pressure exceeds the set value, the valve core moves, opens the passage, releases excess pressure or changes the oil flow direction, thereby protecting the system from high pressure damage or maintaining the required pressure level.

Main types

· Relief valve

Function:Prevent excessive system pressure and provide safety protection.

Application:When the system pressure exceeds the set value, the excess hydraulic oil is automatically returned to the oil tank.

· Pressure relief valve

Function:Reduce and stabilize the pressure of specific branch circuits.

Application:Provide different pressure requirements for different components in the same system.

· Sequence valve

Function:Start different hydraulic actuators in sequence.

Application:In a multi actuator system, control the working sequence of the executing elements.

Characteristics

· High pressure stability: effectively maintaining the required pressure of the system to ensure stable operation of the equipment.

· Security protection: prevent overvoltage damage to the system and extend equipment lifespan.

· Fast response speed: able to quickly respond to pressure changes and adapt to dynamic working conditions.

· Compact structure:Simple design, easy to install and maintain.

Applications

· Hydraulic pressure control valves are widely used in various hydraulic systems, such as:

· Engineering machinery: Control working pressure in equipment such as excavators and cranes.

· Industrial equipment: safety protection and pressure regulation of systems such as hydraulic machine tools and injection molding machines.

· Automotive hydraulic system: used for pressure control of braking and suspension systems.

· Through precise pressure control, hydraulic pressure control valves ensure efficient and stable operation of the system, and provide guarantees for equipment safety, which is an indispensable and important component of modern hydraulic technology.