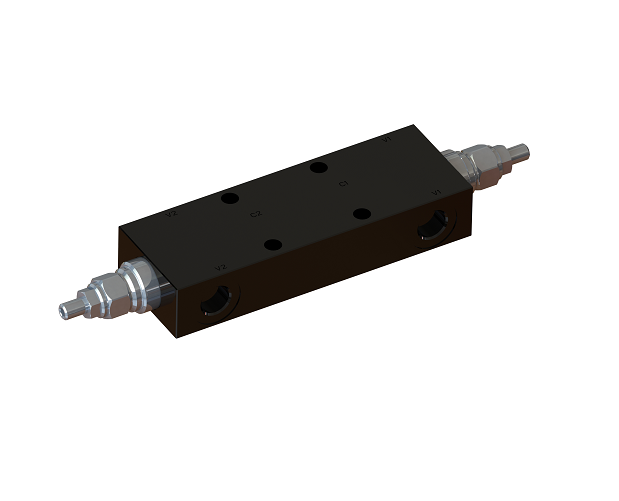

- Products Description

- Main Function

- Parameters

Electro-proporttional valves are advanced hydraulic control components that receive analog electrical signals through electromagnetic coils and adjust the pressure, flow rate, or direction of the hydraulic system proportionally to achieve precise control.Unlike traditional on-off valves, proportional valves can continuously adjust output parameters based on the magnitude of input

Principle of Work

The core of hydraulic electromagnetic valves is a proportional electromagnet, which changes the magnetic field strength according to the input current signal, thereby driving the valve core to continuously move between different positions. The position of the valve core determines the flow rate of hydraulic oil through the valve port or the pressure of the system. Therefore, by changing the input current, continuous adjustment of the output pressure or flow rate of the hydraulic system can be achieved.

Characteristics

Continuously adjustable: capable of achieving stepless adjustment and precise control of pressure or flow based on changes in input signals.

Fast response speed: The proportional electromagnet responds quickly, which helps the system achieve dynamic control.

High control accuracy: Through closed-loop control and sensor feedback, high-precision control can be achieved, reducing system errors.

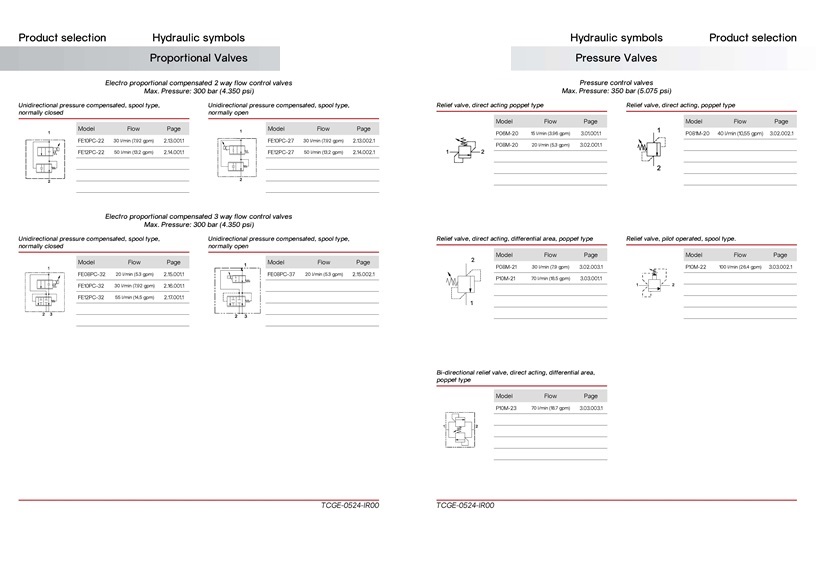

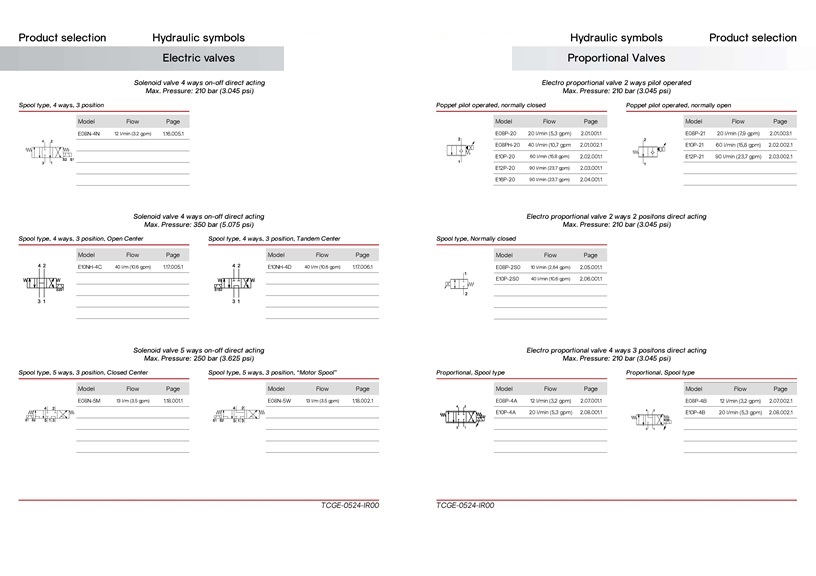

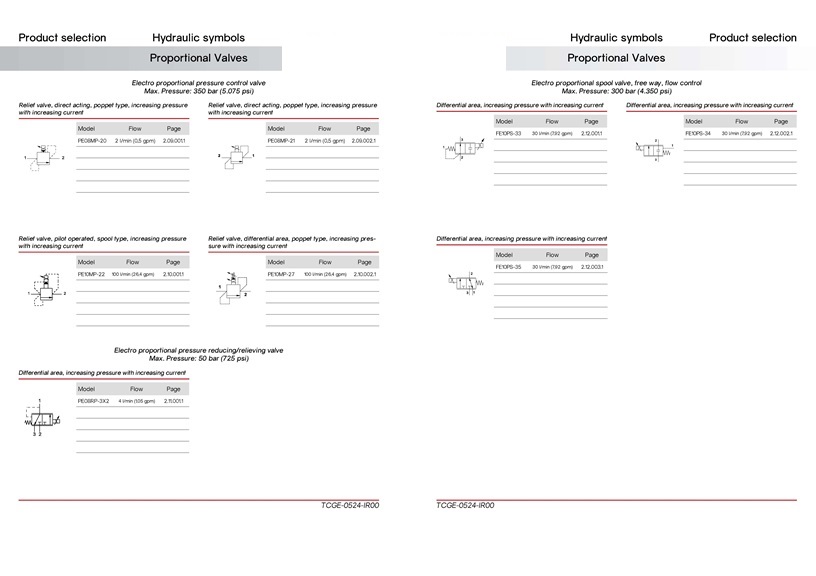

Versatile functions: According to application requirements, it can be divided into different types such as proportional pressure control valves, proportional flow control valves, and proportional directional valves.

Applications

Hydraulic Electro-proporttional valves are widely used in hydraulic systems that require precise control, such as:

Construction machinery: Achieving precise motion control in equipment such as excavators and loaders.

Industrial automation: adjust speed and pressure in CNC machine tools, injection molding machines and other equipment.

Ships and aviation: hydraulic control for stabilizing complex systems.

Hydraulic transmission system: Optimize system performance and improve operational efficiency.

Hydraulic Electro-proporttional valves with its precise, stable, and efficient control capabilities, it has become an indispensable and important component of modern hydraulic systems, helping to improve the automation level and work efficiency of equipment.

Electro-proporttional valves are advanced hydraulic control components that receive analog electrical signals through electromagnetic coils and adjust the pressure, flow rate, or direction of the hydraulic system proportionally to achieve precise control.Unlike traditional on-off valves, proportional valves can continuously adjust output parameters based on the magnitude of input

Principle of Work

· The core of hydraulic electromagnetic valves is a proportional electromagnet, which changes the magnetic field strength according to the input current signal, thereby driving the valve core to continuously move between different positions. The position of the valve core determines the flow rate of hydraulic oil through the valve port or the pressure of the system. Therefore, by changing the input current, continuous adjustment of the output pressure or flow rate of the hydraulic system can be achieved.

Characteristics

·Continuously adjustable: capable of achieving stepless adjustment and precise control of pressure or flow based on changes in input signals.

· Fast response speed: The proportional electromagnet responds quickly, which helps the system achieve dynamic control.

· High control accuracy: Through closed-loop control and sensor feedback, high-precision control can be achieved, reducing system errors.

· Versatile functions: According to application requirements, it can be divided into different types such as proportional pressure control valves, proportional flow control valves, and proportional directional valves.

Applications · Hydraulic Electro-proporttional valves are widely used in hydraulic systems that require precise control, such as:

· Construction machinery: Achieving precise motion control in equipment such as excavators and loaders.

· Industrial automation: adjust speed and pressure in CNC machine tools, injection molding machines and other equipment.

· Ships and aviation: hydraulic control for stabilizing complex systems.

· Hydraulic transmission system: Optimize system performance and improve operational efficiency.

· Electro-proporttional valves with its precise, stable, and efficient control capabilities, it has become an indispensable and important component of modern hydraulic systems, helping to improve the automation level and work efficiency of equipment.

· The core of hydraulic electromagnetic valves is a proportional electromagnet, which changes the magnetic field strength according to the input current signal, thereby driving the valve core to continuously move between different positions. The position of the valve core determines the flow rate of hydraulic oil through the valve port or the pressure of the system. Therefore, by changing the input current, continuous adjustment of the output pressure or flow rate of the hydraulic system can be achieved.

Characteristics

·Continuously adjustable: capable of achieving stepless adjustment and precise control of pressure or flow based on changes in input signals.

· Fast response speed: The proportional electromagnet responds quickly, which helps the system achieve dynamic control.

· High control accuracy: Through closed-loop control and sensor feedback, high-precision control can be achieved, reducing system errors.

· Versatile functions: According to application requirements, it can be divided into different types such as proportional pressure control valves, proportional flow control valves, and proportional directional valves.

Applications · Hydraulic Electro-proporttional valves are widely used in hydraulic systems that require precise control, such as:

· Construction machinery: Achieving precise motion control in equipment such as excavators and loaders.

· Industrial automation: adjust speed and pressure in CNC machine tools, injection molding machines and other equipment.

· Ships and aviation: hydraulic control for stabilizing complex systems.

· Hydraulic transmission system: Optimize system performance and improve operational efficiency.

· Electro-proporttional valves with its precise, stable, and efficient control capabilities, it has become an indispensable and important component of modern hydraulic systems, helping to improve the automation level and work efficiency of equipment.